Creating a Sustainable Future with Eco-Friendly Technology

Implementing a Circular Economy through Waste Plastic Chemical Recycling

Explore Our BusinessAbout Us

TO GREEN PO TECH Co., Ltd.

Established on September 19, 2024, TO GREEN PO TECH is an eco-friendly company creating a sustainable future through waste plastic chemical recycling technology. Located in the Saemangeum Industrial Complex, our company transforms waste plastics into recycled petrochemical raw materials using innovative pyrolysis technology.

Our Business

📌 This business falls under industries applying or manufacturing advanced technologies and products as per Article 5 of the Industrial Development Act.

Waste Plastic Collection

We collect recyclable waste plastics without incineration or landfill.

Collection without Incineration/LandfillChemical Recycling

We chemically recycle waste plastics using pyrolysis.

Pyrolysis Method AppliedRecycled Petrochemical Raw Materials

We produce eco-friendly recycled petrochemical raw materials (pyrolysis oil).

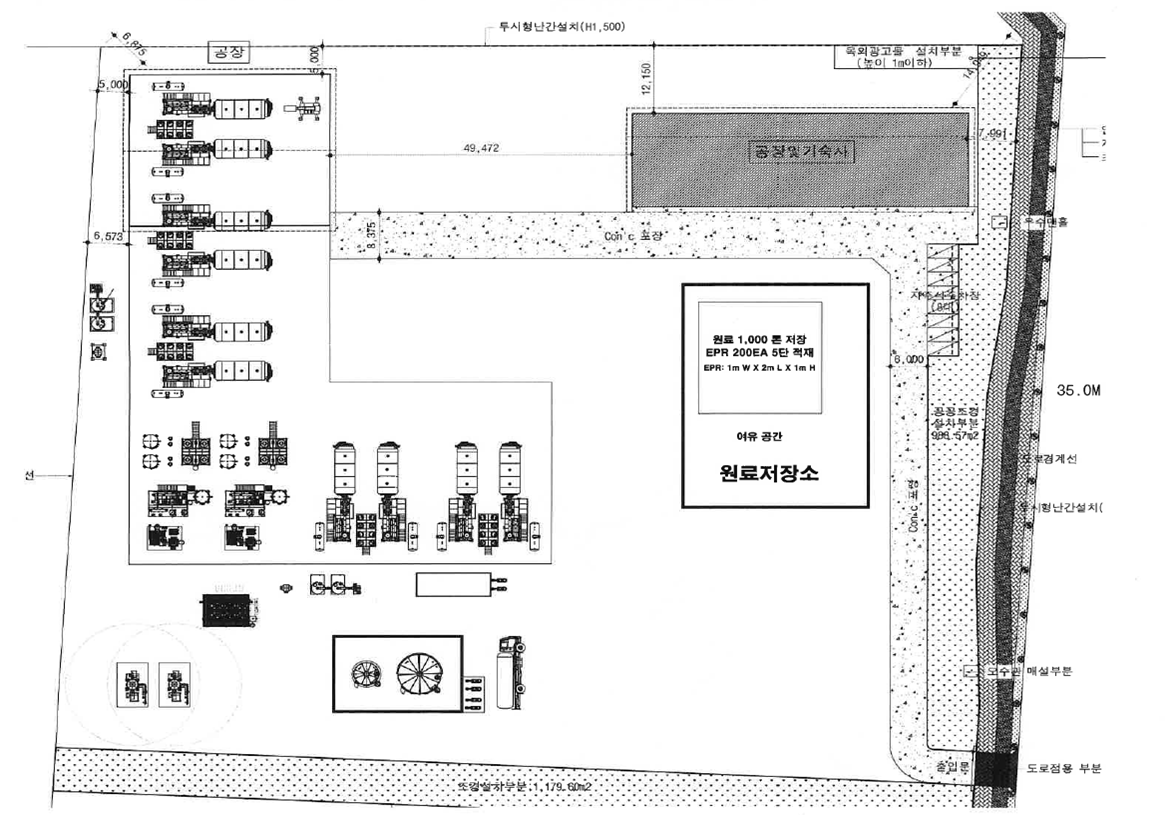

Pyrolysis Oil ProductionProduction Facilities

Total 21 tons/day (10 units) with 6 additional units in Phase 2

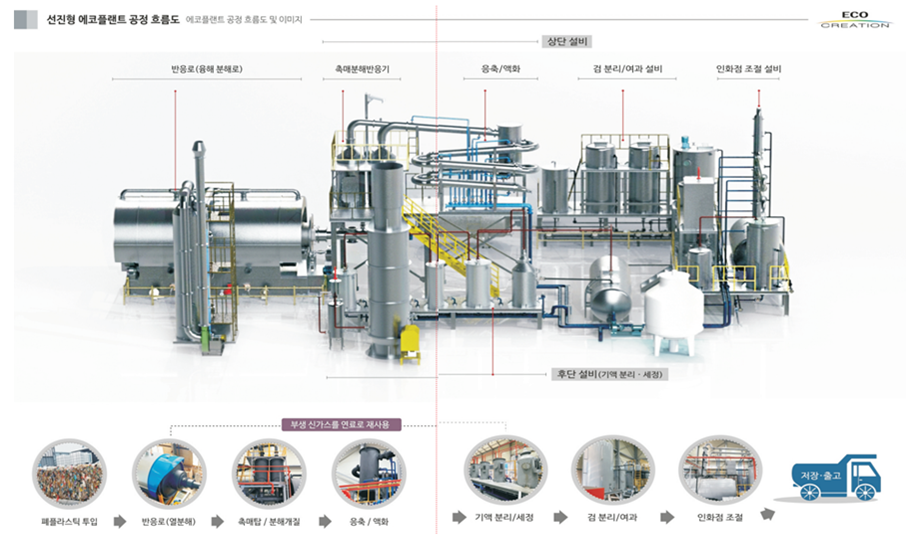

Process and Facility Plan

Process Flow Diagram

Process Photo

Facility Layout Plan

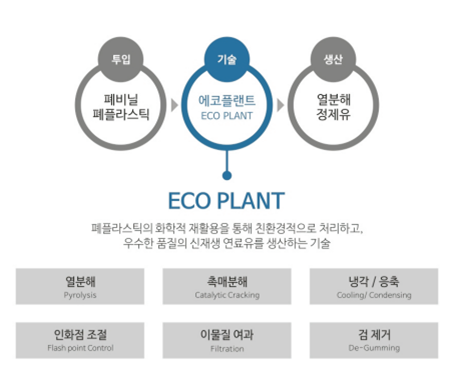

Our Technology

Advanced Technology

Waste gasification and syngas utilization for raw material conversion technology

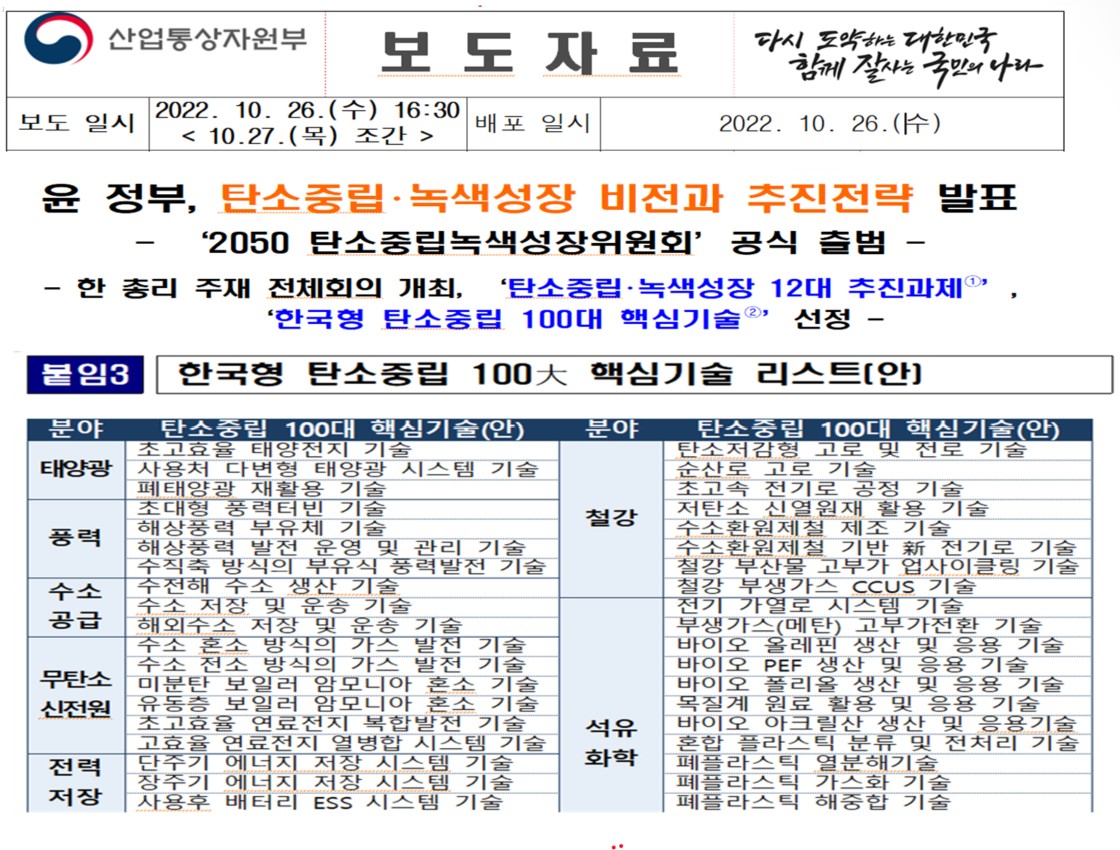

Core Technology

Waste plastic pyrolysis technology (Top 100 Carbon Neutral Core Technologies)

This is an industrial raw materialization technology through chemical recycling of waste plastics, falling within the scope of new growth and original technologies as per Annex 7 of the Enforcement Decree of the Restriction of Special Taxation Act.

Top 100 Carbon Neutral Core Technologies

Selected as a core technology for achieving carbon neutrality by the government

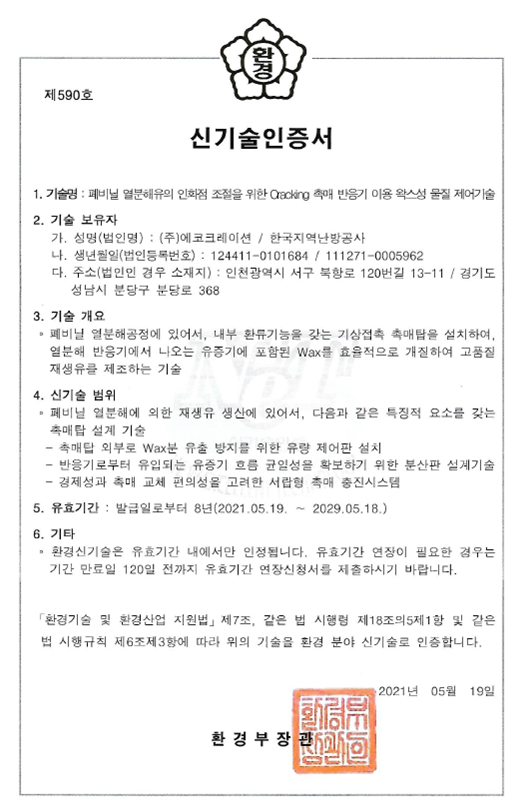

New Technology Certification

Acquired new technology certification for waste plastic pyrolysis technology

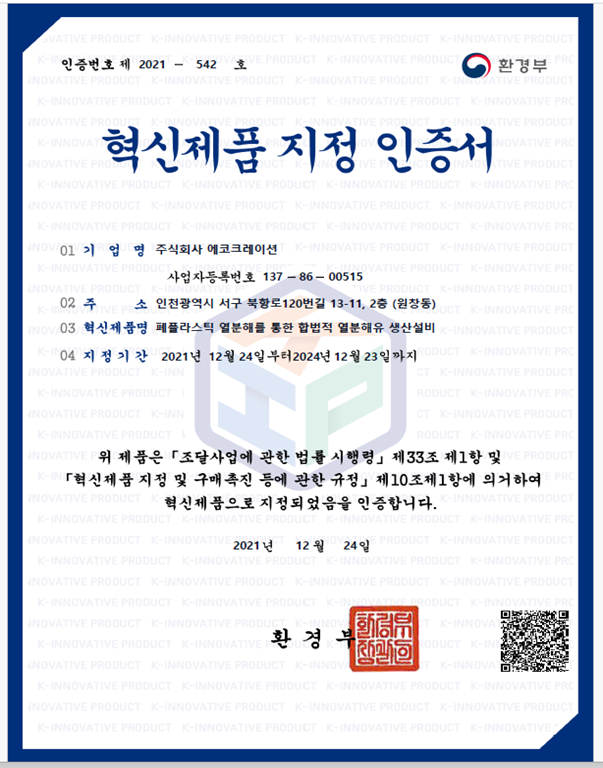

Innovative Product Designation Certificate

Acquired innovative product designation certificate from the Ministry of Environment

Chemical Recycling Technology for Producing Recycled Petrochemical Raw Materials

| 1 Unit Processing Capacity | Max 8 tons/batch (Reactor volume 40㎥) | Fuel Used | LPG, Non-condensable gas (Syngas) |

|---|---|---|---|

| Process Time | Pyrolysis: 14~16hr/batch Cooling time: 6~7hr additional |

Catalyst Used | Decomposition and Isomerization Catalyst |

| Reactor Type | Rotary Kiln Type | Pyrolysis Oil Yield | Approx. 60% (4.8 tons/batch) |

| Feedstock Input | Mixed plastics batch input | Pyrolysis Oil Quality | Meets petrochemical raw material standards |

| Decomposition Temperature | 350~480 ℃ (Oxygen-free sealed continuous process) |

Safety Equipment | Explosion-proof, pressure safety valves, etc. |

Directions

Company Information

Inquiry

If you have any questions about TO GREEN PO TECH, please feel free to contact us.